Past Projects

-

Use of Ultra-High Pressure Cleaning to Clear Production Lines

A Glass Fibers for Non-Woven & Textile Applications Customer called after plant workers mistakenly place the wrong product in one of their silos. Canco was able to vacuum product and transfer to correct silo. Customer also has product transfer lines … Continue reading →

-

Cleaning Heat Exchangers

Manufacturer of Chemicals had two heat exchangers offline for two years. Several companies had tried unsuccessfully clean them. After hearing about Canco’s 55kpsi units, Canco was able to come in and clean both units resulting in both units being placed … Continue reading →

-

Site Cleanup of Wood and Plywood

Customer had sludge pit full of waste product. CANCO was able to come onsite and remove 212 tons of waste product and deliver it to an EPA approved waste facility.

-

Cleaning of Rail Tank Cars

Canco was called in to clean rail cars for transportation.

-

55K Ultra-High Pressure Hydro Blasting Used to Remove Solidified Product

Manufacturer of Resins Used for Coatings needed solidified product removed from one of their chemical reactors. Other companies had tried to remove the product unsuccessfully using various methods, including drilling holes and using blasting caps. After giving up on those … Continue reading →

-

Specialty Vacuuming Production Waste

A Manufacturer of Stainless Steel Products needed heavily accumulated metal shavings removed from their production area. CANCO vacuumed all of the waste product from the production area and returned them to a safe work environment.

-

EPA Certified Recycling Project

Customer has multiple sludge pits. They rely on CANCO to remove the waste product from these pits and dispose of it in EPA approved disposal facilities.

-

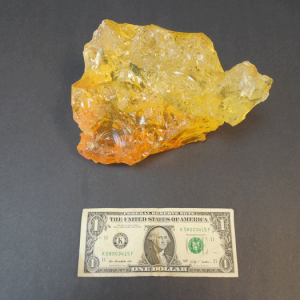

Use 55K Ultra-High Hydroblasting to Remove Accumulation of By-Product

A Manufacturer of Glass Products uses heavy duty furnaces in their glass production facility. They rely on CANCO to remove the hardened accumulation of glass making byproduct from the inside walls and floors of their furnaces using 55K PSI Ultra-High … Continue reading →

-

Specialty Vacuuming – Cleaning and Dusting

A manufacturer of paper products had accumulated dust on the rafters of their manufacturing facility. This dust, which is a result of their manufacturing process, must be kept below 1/16 of an inch to meet OSHA guidelines. They rely on … Continue reading →

-

Cleaning Chemical Reactors with Less Down Time

A Manufacturer of Polymers and Adhesives had multiple chemical reactors in their manufacturing facility. During the manufacturing process, layers of polymers and adhesives would accumulate on the inside of their reactor mixing bowls. Over time this buildup acts as an … Continue reading →